Service Details

We specialize in manufacturing and supplying high-performance wear parts for cement and mining industries, including critical components like grate plates, hammers, liners, and roller segments. Our expertise extends from material selection and hardfacing technology to pattern design and quality assurance. We ensure optimal wear resistance and extended service life through advanced metallurgy and precision manufacturing processes.

Service Benefits

- Extended component service life through optimized metallurgy

- Custom-engineered solutions for specific wear conditions

- Comprehensive material testing and quality certification

- Technical support for installation and maintenance

- Cost-effective wear management solutions

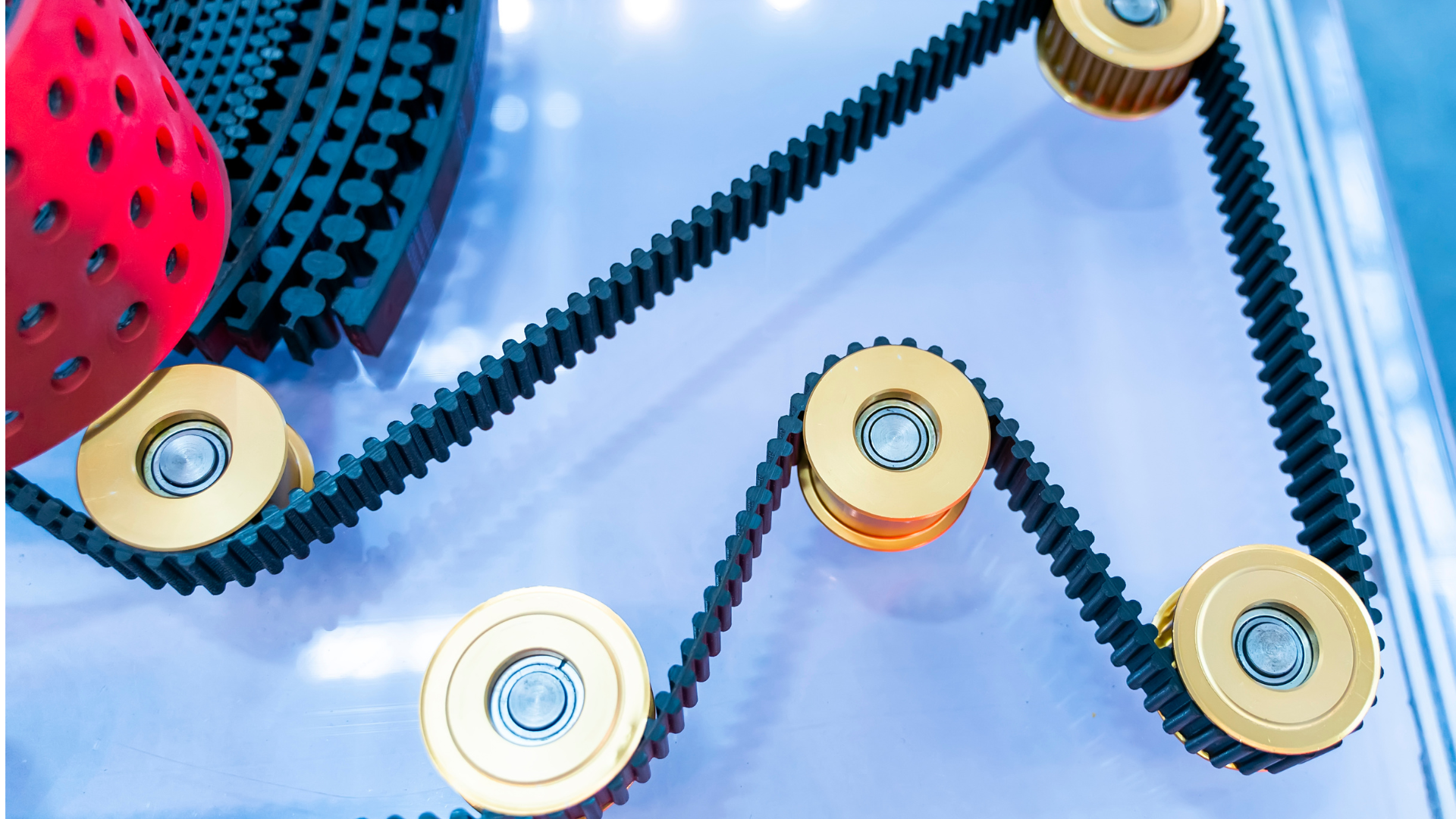

Casting & Wear Parts Supply Expertise

We manufacture a comprehensive range of wear-resistant components including grinding media, mill liners, classifier parts, crusher wear parts, and conveyor components. Our portfolio covers both standard and custom-engineered solutions for specific applications. We also provide specialized components like high-chrome grinding media, composite wear plates, and hardfaced components for extreme wear conditions.

We employ advanced metallurgical processes including precise heat treatment, controlled cooling, and specialized hardfacing techniques. Each component is designed with optimal material composition and hardness profiles for specific wear conditions. We also provide detailed installation guidelines and wear monitoring protocols to maximize component life in operation.

Our material selection process involves detailed analysis of operating conditions including impact loads, abrasion patterns, and chemical exposure. We utilize various grades of high-chrome iron, manganese steel, and composite materials, each optimized for specific applications. Our metallurgical lab ensures consistent material properties through regular testing and quality control.